Sistema de Producción Integrada.

50 Estaciones de control repartidas por 14.000 Has productivas.

Ingenieros asesorando a los agricultores durante todo el año.

Control riguroso de tratamientos y abonos.

Sistema de Producción Integrada.

50 Estaciones de control repartidas por 14.000 Has productivas.

Ingenieros asesorando a los agricultores durante todo el año.

Control riguroso de tratamientos y abonos.

Gestor de patio.

Temperatura, aspecto, aroma, daños o síntomas de plagas,…

Cada entrega de aceituna se clasifica a la llegada para que nunca se procesen por la misma línea aceitunas de distinta calidad.

Muestra mecanizada y aleatoria de cada lote para el laboratorio.

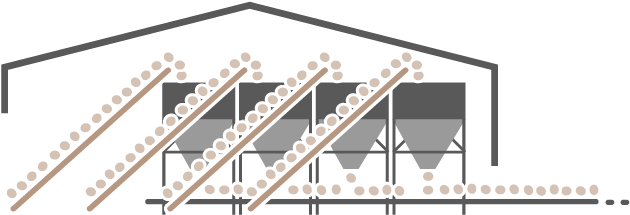

2 patios, 5 líneas por patio para el procesado independiente de las aceitunas de distintas calidades.

Todas las superficies en contacto con la fruta tratadas con pintura alimentaria.

Tolvas independientes con molinos automatizados dispuestos al aire libre para disipar temperatura.

Cintas de transporte de calidad alimentaria.

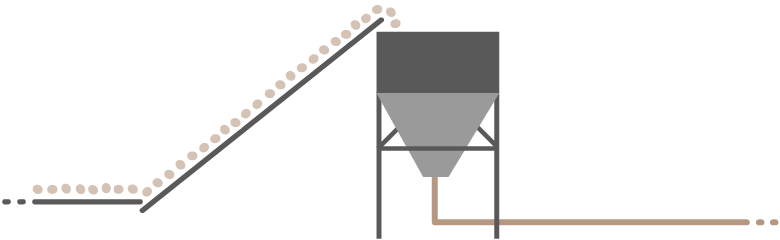

Extracción en frío. Control riguroso y automático de temperaturas. Líneas de procesado independientes según calidad.

Registro continuo de temperaturas y de todas las variables de proceso.

Sostenibilidad: Todas las necesidades de calor y agua caliente se cubren con una caldera que quema el orujillo obtenido como subproducto.

Todos los subproductos se tratan o venden a otras industrias (hojas, orujos y agua para la comunidad de Regantes).

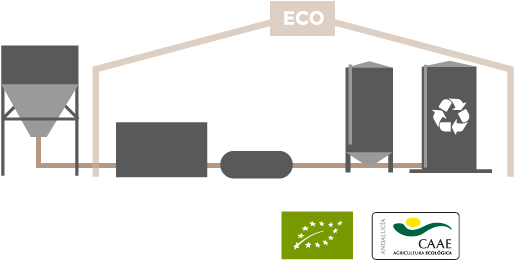

Línea Homologada totalmente independiente para Aceites Ecológicos: Tolva - Extracción en frío - Aclaradores - Depósitos.

Panel de cata profesional asigna calidad y destino en Bodega.

El sistema de trazabilidad permitirá corroborar si existen desviaciones respecto a lo previsto por el gestor de patio y los análisis de muestras en laboratorio.

Aclaradores de 50 Tons. Antes de enviarse a bodega los aceites recién extraídos se catan para ser clasificados.

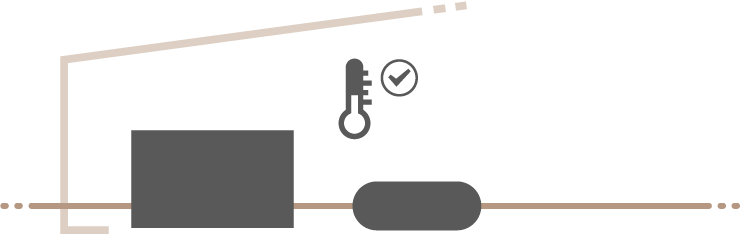

Toda la bodega está bajo cubierta, protegida de la radiación solar y los elementos y a temperatura regulada controlada automáticamente

Los AOVE se almacenan ya filtrados para mejorar su estabilidad y conservación óptima.

Mejora permanente, sometida a los más estrictos controles nacionales e internacionales.

Más de 100 depósitos de Acero Inox pulido y reluciente como espejos de 50 y 100 Tns conservan el aceite en las bodegas de Conde de Benalúa.

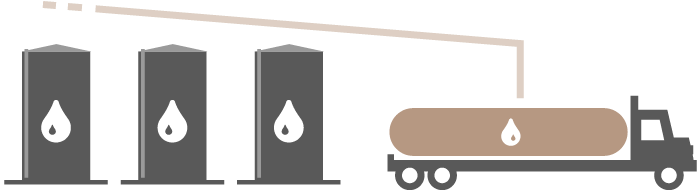

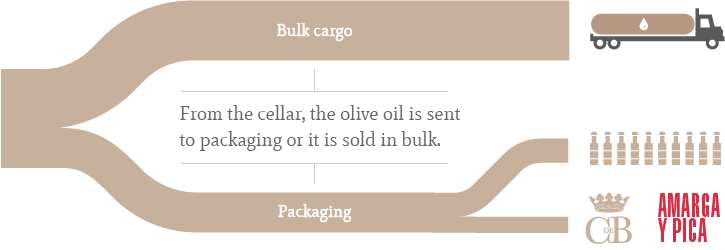

Control riguroso antes de la carga y sellado de los transportes una vez cargados.

Para garantizar su calidad todo producto antes de ser envasado es analizado en laboratorios expertos acreditados por ENAC.

Al final de la campaña las instalaciones se limpian cuidadosamente y toda la maquinaria se desmonta, limpia y se guarda protegida hasta la campaña siguiente.

El laboratorio interno de Conde de Benalúa procesa en 24hrs muestras ciegas de todos los lotes. Se obtienen rendimientos, acidez y peróxidos. El aceite una vez analizado se pone a disposición del panel de Cata.

El panel de cata clasifica cada muestra anónima. AOVE, AOV ó Lampante. El lote queda caracterizado por su Cata y Análisis.

Control de calidad: Panel de CATA profesional.

Los Departamentos de Calidad y Producción supervisan y controlan en tiempo real todos los procesos, los aforos, las cargas de trabajo... Tecnología de vanguardia para ofrecer siempre el mejor servicio.

Estamos desarrollando nuestro nuevo sistema. Mientras tanto...

Puedes continuar navegando por aquí.

Contactamos con usted

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.